Perfit FS

PERFECT CHAIRSIDE SOLUTION

FOR ONE-VISIT PROSTHESIS

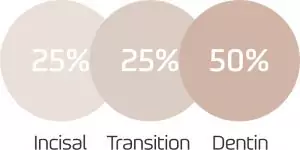

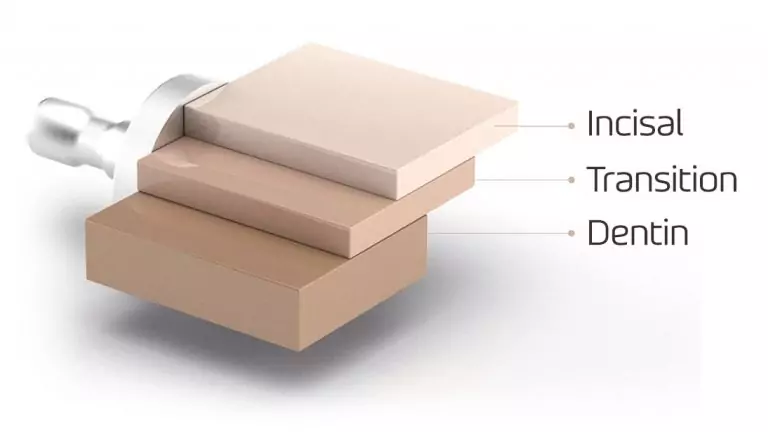

Ultimate naturalness

The seamless 3-layered structure.

Fast workflow

Save time, as no firing required.

High level of crack resistance

After Vickers indentation at 10kg load.

Compared to conventional general zirconia disc (3Y-TZP) and glass ceramic, Perfit FS shows no apparent cracks emanating from the corners of the diamond indentation, indicating its exceptional fracture toughness.

In conclusion, restorations of Perfit FS have greater crack resistance than other types of restorations shown below.

500 MPa, High Flexural Strength

Wide range of Indications.

Frequently asked questions

Is Perfit FS made of zirconia?

Yes. This product is made of 100% zirconia.

Does Perfit FS block require a firing process?

Firing is not needed since Perfit FS blocks are fully crystallized (sintered).

How many sizes are available?

Perfit FS is available in 4 sizes:

- I12 (15.0 X 12.0 X 10.4)

- C14 (18.0 X 14.0 X 12.7)

- C16 (18.0 X 15.9 X 17.8)

- B32 (32.0 X 15.1 X 15.1)

Which milling machines are compatible with Perfit FS?

*Before using Perfit FS, technical support requires your milling machine to check the milling strategy including the tool and CAM system.

Available Milling Machines

| Milling Machine | S/W | Tool Life |

|---|---|---|

Imes-icore

|

Millbox hyperDENT | Over 20 units (Perfit Customized Bur) |

Dentsply Sirona

|

inLab S/W Cerec S/W |

25 Blocks (Pointed Bur) 12 Blocks (Step Bur) |

Roland DG

|

MillBox | Over 20 units (Perfit Customized Bur) |

Is it possible to stain Perfit FS?

Perfit FS can be stained and glazed by using various manufacturers’ products.

Is it possible to polish the surface of Perfit FS?

High gloss polishing is not recommended as it can decrease the strength and aesthetic compared to glazing.